Pet Toy Project

About This Project

• Initially a final project for a Design and Making course, this group project was awarded a 3rd place prize amongst over 100 teams at the UNC Makerfest 2025.

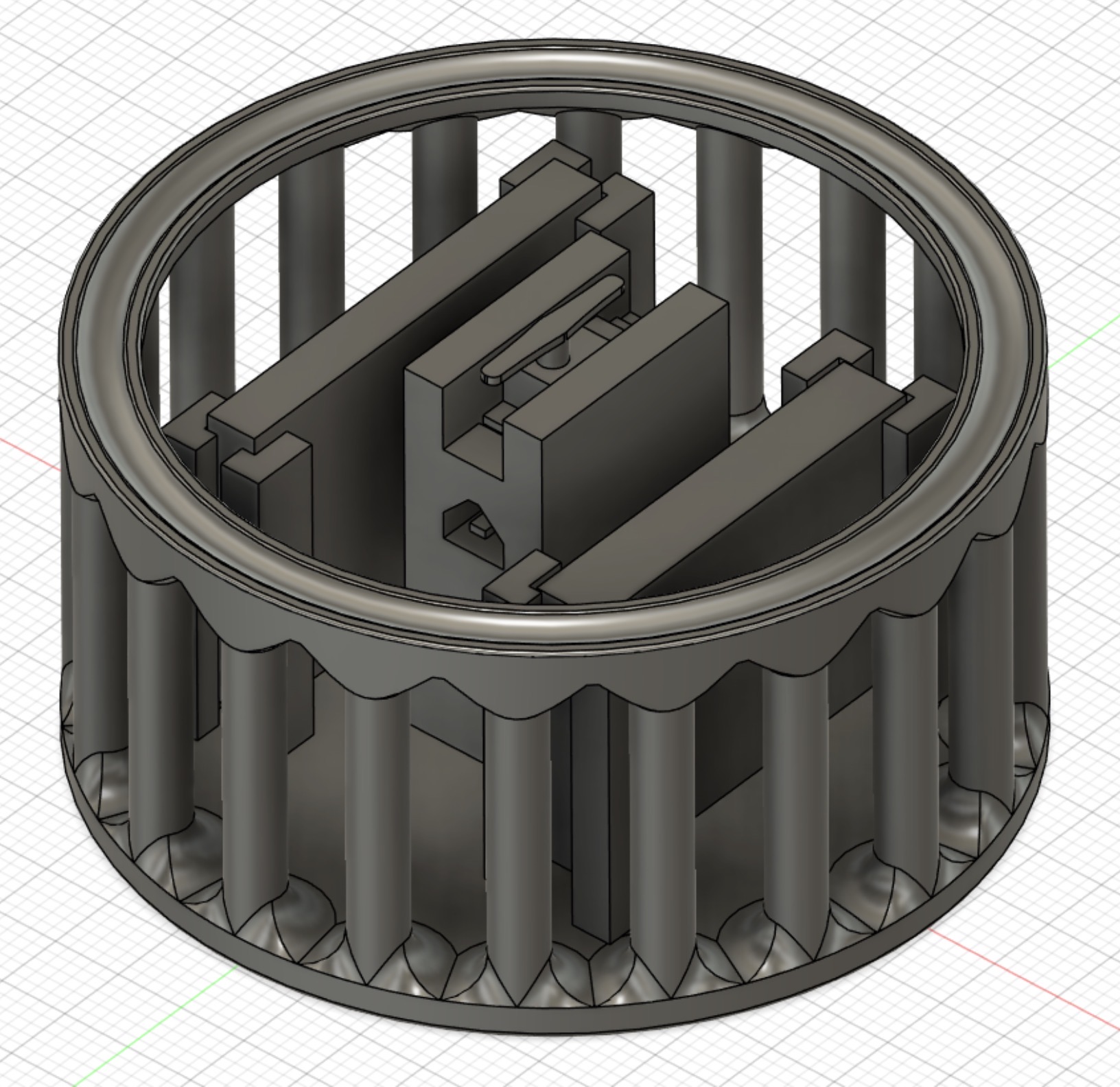

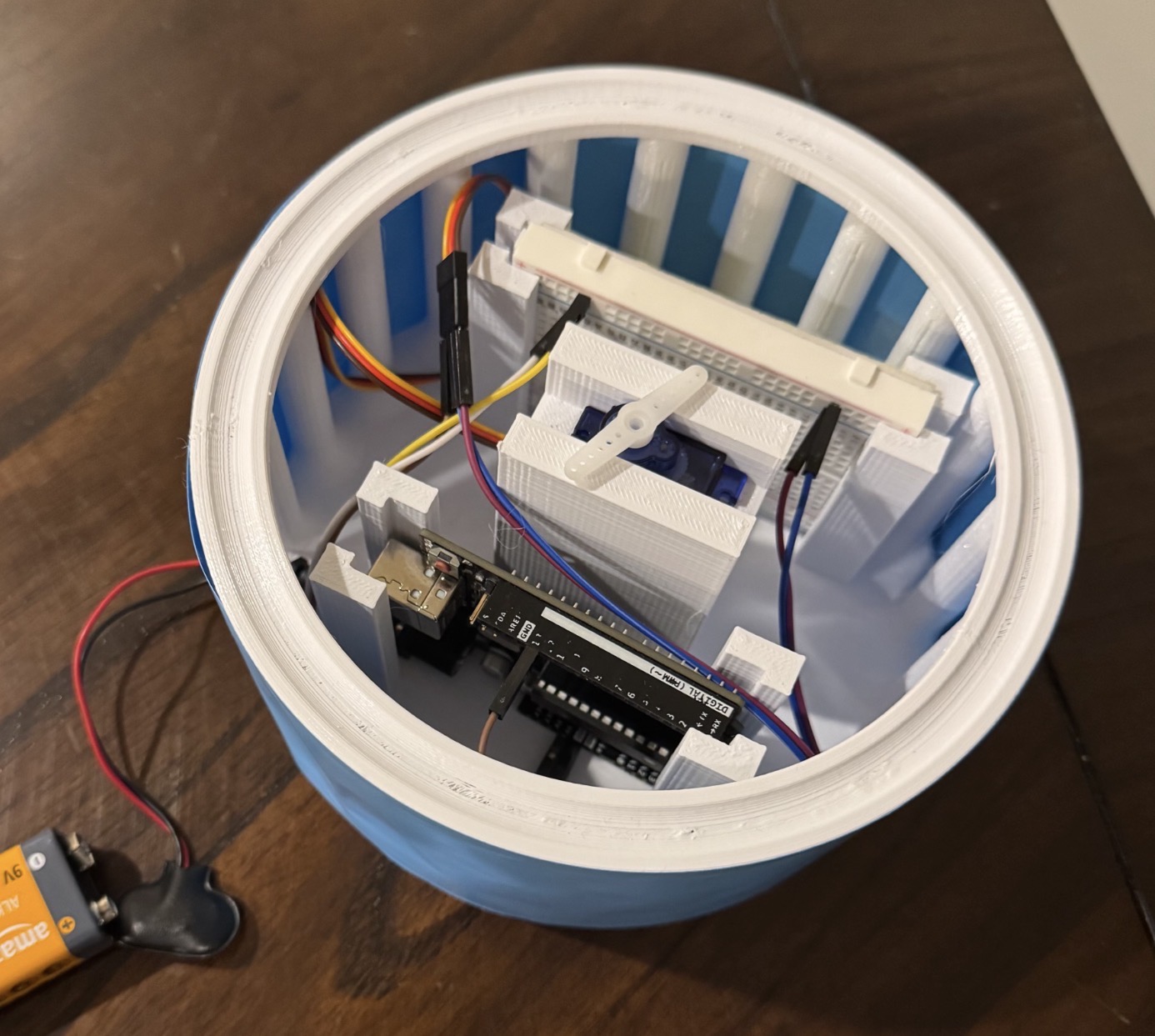

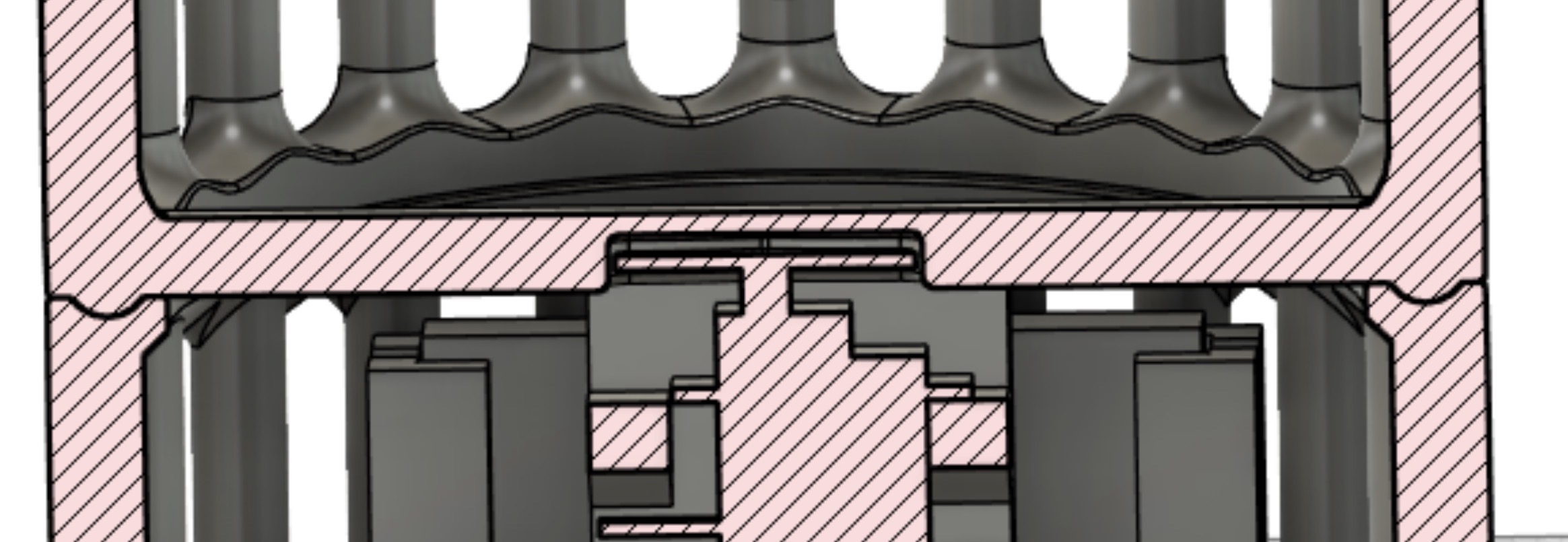

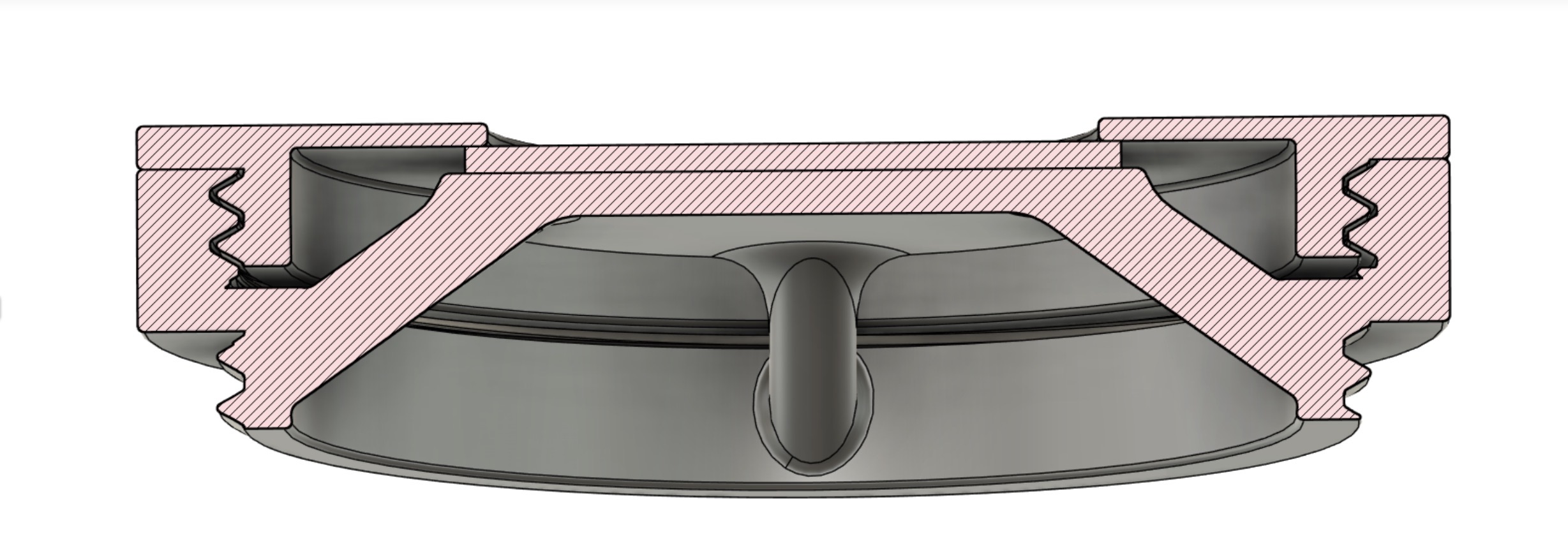

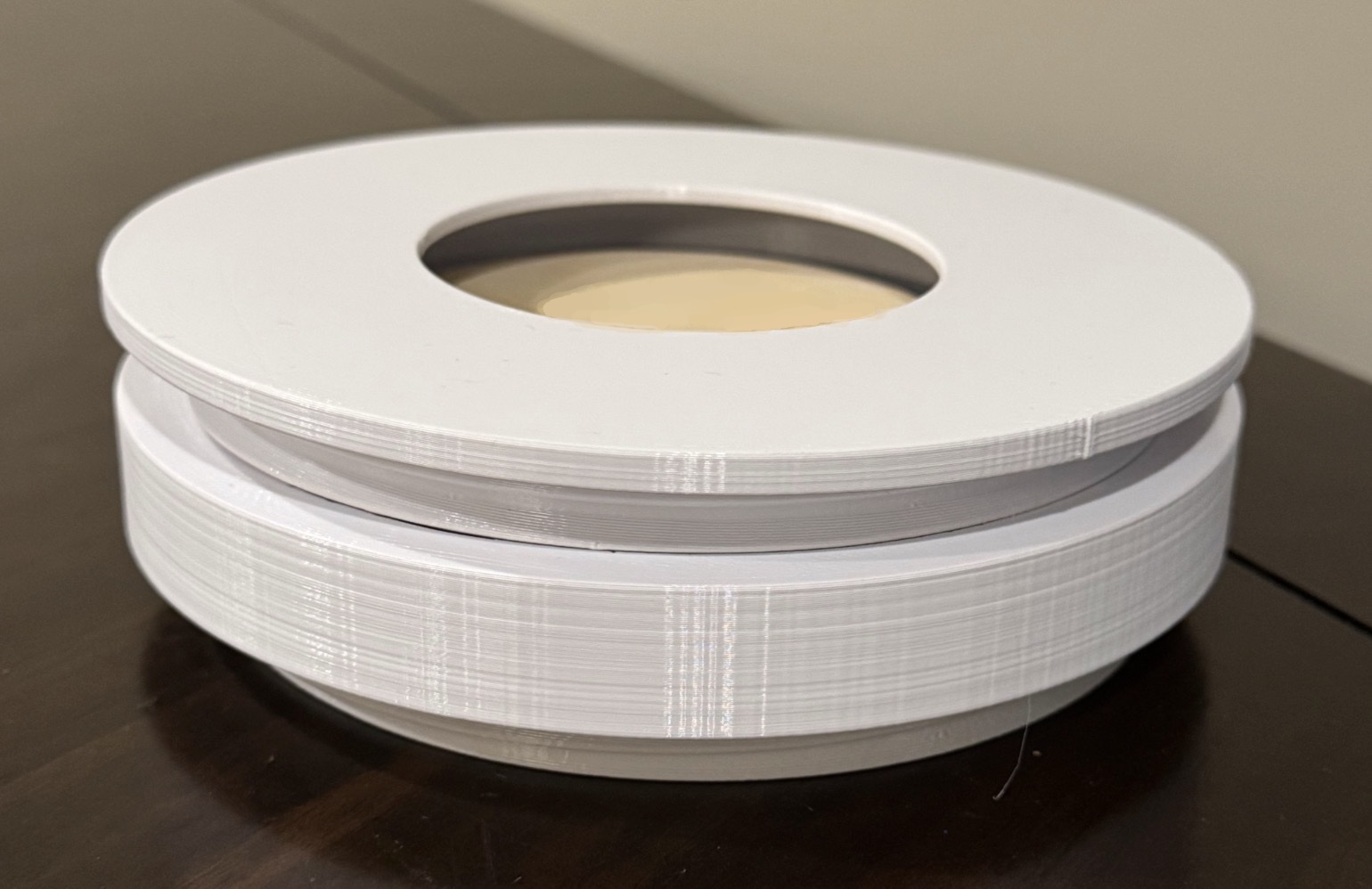

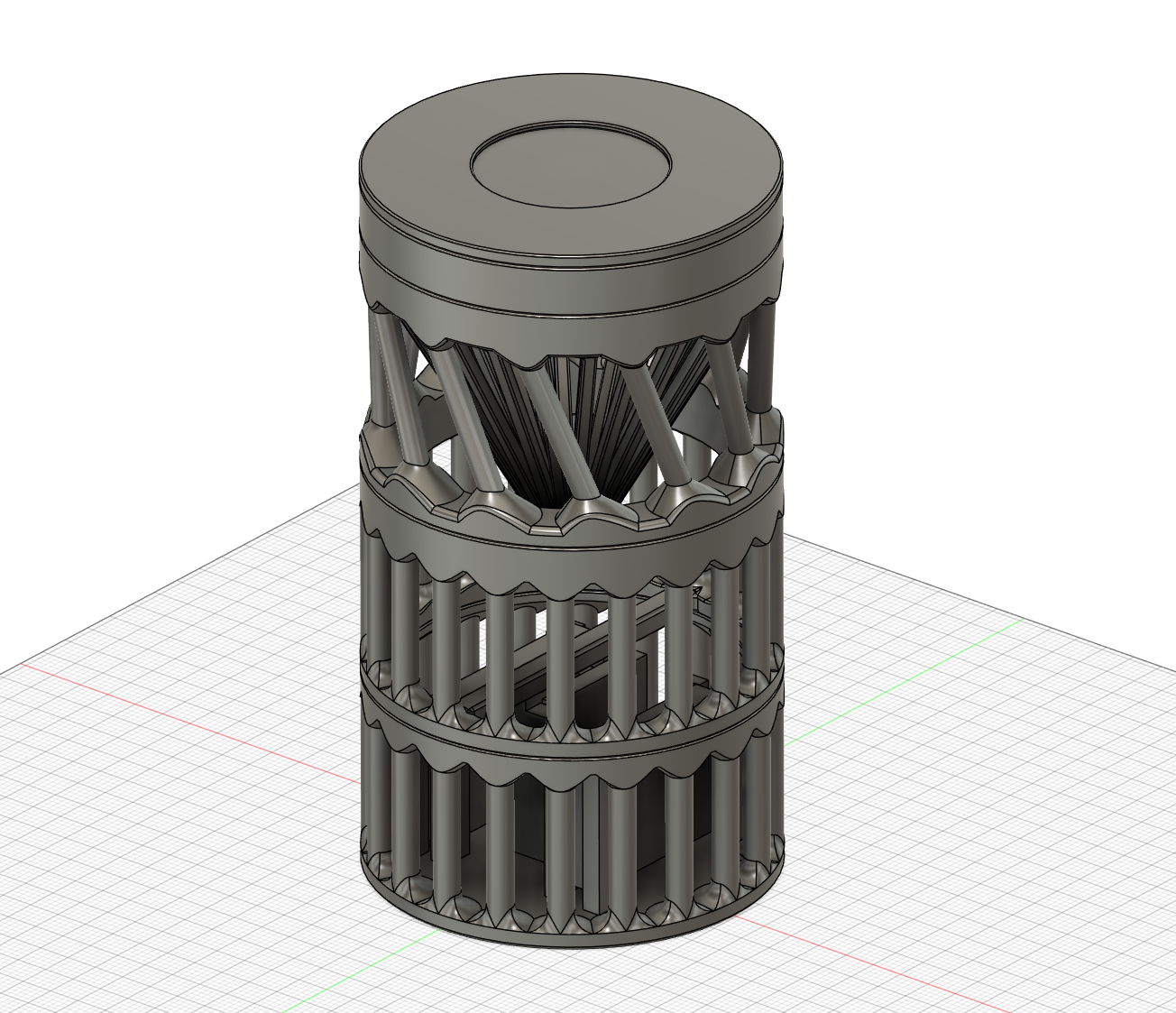

• To achieve the assignment requirements, as well as to remain within assignment design constraints, the final implementation included a custom designed and hand-wired circuit board and motor programmed in C++ to achieve fine motion control, with a multi-part 3D frame designed in Autodesk Fusion and printed with Fusion3 3D Printer.

• The bottom layer of the design hosts the motor and circuitry driving the motion control of the layers above, facilitated through a circular track between the first two layers. Subsequent layers secure together seamlessly with a 3D printed and custom fit thread.

Technologies Used

Challenges & Learnings

• This project culminated multiple methods of applied engineering which had been introduced throughout the semester length course; 3D Computer Aided-Design, 3D printing Slicer Software, multi-part 3D printing, custom wired circuitry with custom programmed circuit controller, and custom programmed laser cutter fabrication and engraving.

• Our team consisted of 5 individuals of varying skillsets and experience levels, such that each stage of the design and production process could be overseen by the team member with the most relevent experience for the given task.

• The most personal difficulty was experienced balancing clearly communicating design visions to the team, and organizing the logistics and order of when individual team members tasks occured in the production process.

Project Gallery